https://riverbendmalt.com/wp-content/uploads/2023/10/Plow-To-Pint.jpg

1206

1316

Scott Hickman

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Scott Hickman2023-10-25 17:16:402023-10-30 11:34:15Plow To Pint Pilsner

https://riverbendmalt.com/wp-content/uploads/2023/10/Plow-To-Pint.jpg

1206

1316

Scott Hickman

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Scott Hickman2023-10-25 17:16:402023-10-30 11:34:15Plow To Pint PilsnerPROCESS

Consistent quality from small batch to large scale.

At Riverbend, we pride ourselves in honoring age-old traditions while combining modern techniques and artisan flair to produce exceptional craft malt.

Yes, we still hand-rake our grain during germination.

Yes, we can ship out 4,000 pounds shipped within one day of the order.

Yes, you’re invited to work with our experts to create a custom malt flavor for both small-batch and large-scale craft beer and craft spirits recipes.

We think our malt is the best in the business, but you’ll have to try it to find out.

See our malting process in action in our Asheville, NC production facility

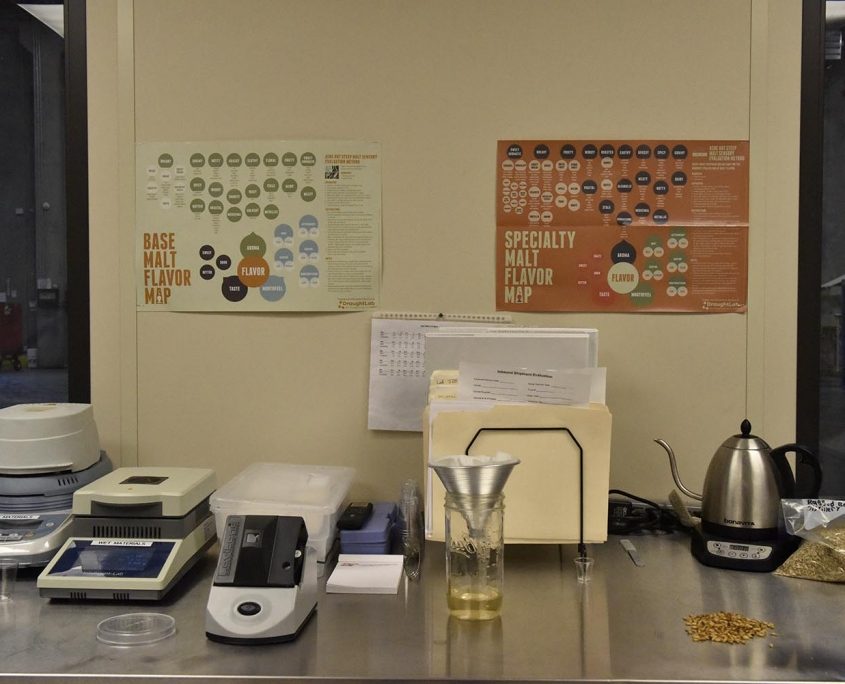

STEP BY STEP PROCESS

STEP ONE

RAW MATERIALS

Over the years, we have built strong relationships with our farmers. All of our grains are sourced from within a 500-mile radius of the malt house. This practice allows us to bring high-quality, locally-sourced grain to our brewing and distilling partners across the Southeast.

STEP TWO

FLAVOR DEVELOPMENT

Whether we are working with a new experimental variety or a trusted heirloom grain, the goal is the same– great flavor. Subtle changes in each step of the process can lead to improved performance and taste. This process requires near-constant monitoring and testing, but the end product is always worth it!

STEP THREE

PRODUCTION

Traditional hand-raked floor-malt is at the heart of our company. This is how we learned our craft and how we innovate. We couple this system with our state-of-the-art GKVs (Germ-Kiln-Vessel) to meet the volume demands of our customers.

The first step in the malting process is steeping. During steeping, water is absorbed by the raw barley kernel and germination begins. Steeping starts with raw seed that has been sorted and cleaned, then transferred into steep tanks and covered with water. Water is crucial to the malting process, providing the medium for the biochemical reactions that occur inside the seed kernel.

For the next three days, the raw grain is submerged and periodically uncovered, allowing the grain to rest and respiration to occur. The absorbed water activates the enzymatic process. This process, in turn, initiates the growth of the acrospire (sprout).

Steeping is complete when the barley has reached a sufficient moisture level to allow uniform breakdown of the starches and proteins.

One visual indicator that the maltster uses to determine the completion of steeping is to count the percentage of kernels that show “chit.” Raw grain that has been properly steeped is referred to as “chitted,” the “chit” being the start of the rootlets that are now visibly emerging from the embryo of the kernel.

The chitted barley is transferred from the steep tank to the germination floor. Germination, which began in the steep tank, continues in the compartment where the barley kernel undergoes modification.

“Modification” refers to the breakdown of the protein and carbohydrates and the resulting opening up of the seeds’ starch reserves. Good modification requires the barley to remain on the floor until it is fully modified.

Periodic turning of the barley keeps the grain bed from becoming too warm and rootlets from “felting” or growing together.

The germination process is halted by drying. If germination was allowed to continue, the kernel would continue to grow, and the growing plant would use all of the starch reserves needed by the brewer.

Once the green malt is removed from the germination floor, it is sufficiently dried before being kilned at a significantly higher temperature. This is the proper process to produce the ideal base malt.

Specialty malts are dried in a kiln at higher temperatures for more extended periods, roasted, or both. Varying the moisture level and time and temperature of drying develops the flavor and color characteristics of each specialty malt.

The grain must be cleaned once kilning is complete, prior to shipping. The objective of cleaning is to remove all of the rootlets, thin kernels, and broken kernels from the finished product.

Cleaning is a two-step process involving a debearder and a seed cleaner. First, the debearder removes the rootlets and polishes the kernels.

Next, using a series of sorting screens and high-powered fans, the seed cleaner sorts out the plump kernels from the rootlet material and thin kernels.

STEP FOUR

LAB TESTING & QUALITY CONTROL

Each batch undergoes extensive testing before it can be shipped. Our testing process includes a complete sensory evaluation as well as third-party analysis. This ensures that only the highest-quality product makes it out the door to our customers.

STEP FIVE

SHIPPING, DELIVERY, OR PICKUP

Orders of up to 4,000 lbs. placed before noon Monday through Thursday can ship the same day. (Orders placed on Friday will ship the following Monday.) Local and regional customers can pick up their orders at our Asheville, NC, malt house. Or, if you’re one of our Asheville neighbors, your local order can be delivered to you free of charge!

https://riverbendmalt.com/wp-content/uploads/2023/10/Plow-To-Pint.jpg

1206

1316

Scott Hickman

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Scott Hickman2023-10-25 17:16:402023-10-30 11:34:15Plow To Pint Pilsner

https://riverbendmalt.com/wp-content/uploads/2023/10/Plow-To-Pint.jpg

1206

1316

Scott Hickman

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Scott Hickman2023-10-25 17:16:402023-10-30 11:34:15Plow To Pint Pilsner

Fig Wood Smoked Pilsner

Biltmore Pale Malt

Farmhouse Pilsner

Chaos Magician

Straight Rye Whiskey

https://riverbendmalt.com/wp-content/uploads/2021/05/old-tuffy-new-belgium-1.jpeg

275

183

Brent Manning

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Brent Manning2021-05-04 10:08:252021-05-04 10:08:25Old Tuffy

https://riverbendmalt.com/wp-content/uploads/2021/05/old-tuffy-new-belgium-1.jpeg

275

183

Brent Manning

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Brent Manning2021-05-04 10:08:252021-05-04 10:08:25Old Tuffy

Orange Krush

Smith Mountain Lager

Tennessee Haze

https://riverbendmalt.com/wp-content/uploads/2021/05/YeeHaw-cerveza-1.jpeg

259

194

Brent Manning

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Brent Manning2021-05-03 16:09:292021-05-03 16:09:29Cerveza

https://riverbendmalt.com/wp-content/uploads/2021/05/YeeHaw-cerveza-1.jpeg

259

194

Brent Manning

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Brent Manning2021-05-03 16:09:292021-05-03 16:09:29Cerveza

All Malt

Grambling Woods Rye Malt Whiskey

Tennessee Whiskey (Bottled in Bond)

Dark Rhythm Gin

Biere de Riverbend

bierederiverbend

Italian Pilsner

Obliterated Mind

IPA

https://riverbendmalt.com/wp-content/uploads/2019/08/DSSOLVR-CzechPils-1.jpeg

225

225

Mark Burrell

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Mark Burrell2019-08-13 21:20:362023-07-25 17:33:46Believe in the Breeze

https://riverbendmalt.com/wp-content/uploads/2019/08/DSSOLVR-CzechPils-1.jpeg

225

225

Mark Burrell

https://riverbendmalt.com/wp-content/uploads/2019/05/Riverbend-Malt-for-Craft-Beer.png

Mark Burrell2019-08-13 21:20:362023-07-25 17:33:46Believe in the Breeze

Mystik Bock

Mystic Bock

Appalachia

Appalachia

Regent’s Rye Tripel

Tripel

Riverbend Rye

Fille de Ferme

Farmhouse Ale

Blade and Sheath

Belgian Saison

Let’s brew up something good.

Talk to our expert maltsters about the best malt for your project or work with us to create a custom malt.