Wow! Hard to believe we’ve been malting for over a year at this point. Over the past 12 months we’ve encountered all of the typical “start up” problems, cost overruns, permitting headaches, inefficient supply chain issues, etc. all of which contributed to a roller coaster ride. Aaah, but now we’ve hit the sweet spot.

Now, you are probably asking yourself, what is the “sweet spot” for a malt house? Well, it has a lot to do with climate control. Our barley likes a cool, humid space to germinate. While we knew this was important on day 1, we did not achieve full control over our germination room’s climate until many months down the road.

This penchant for climate control extends into the kilning process. When we started, we had insufficient heat and air flow to kiln large batches. This meant that our output was far below what it takes to “break even”. The only solution was to spend more money….new fan, more heaters, more duct work. The end result is a 10’x10′ that works like a Swiss watch.

Together, these pieces of the puzzle now contribute to a (relatively) smooth running machine that kicks out 7-8 batches of high-quality, artisan malt per month!

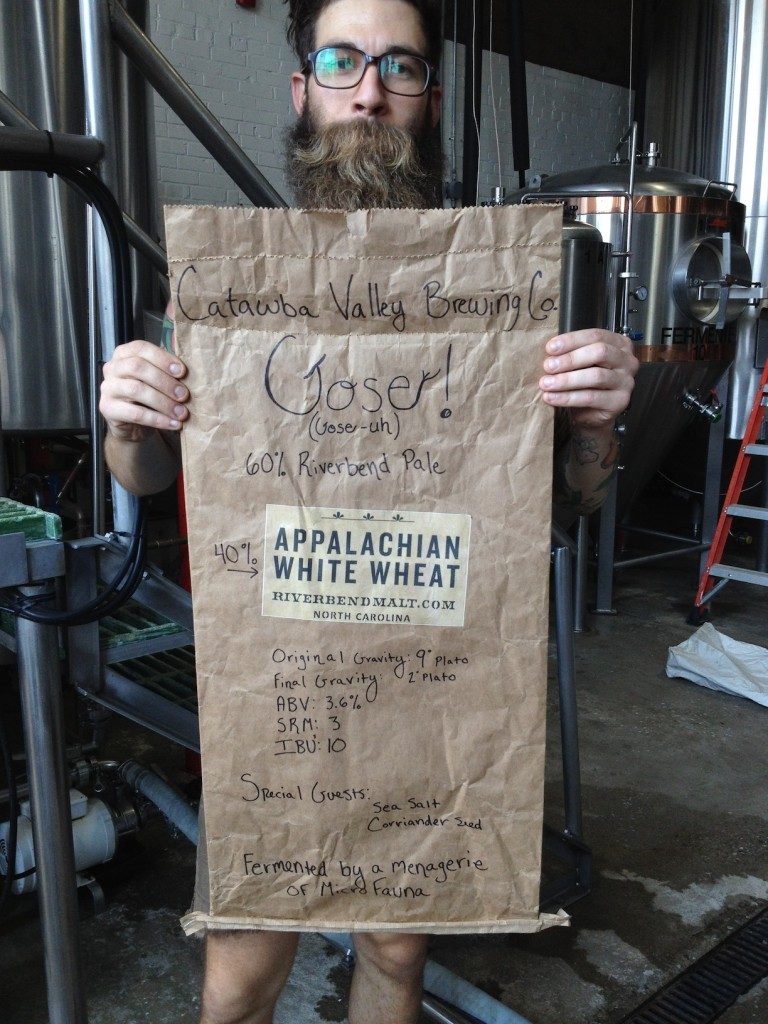

Where are these batches heading? To several local breweries around Asheville this fall! Stop by the Wedge for an NC Pale Ale (featuring Echoview Farm hops!) this weekend and raise a glass to your local grain farmer, hop grower, and maltster….we’re working hard to create a new craft beer economy throughout our state.

A delicious, dry hopped NC Pale Ale…now available at the Wedge