November Expansion Update

There comes a time in most every business owner’s journey when they have to decide: are we going to really commit and take this thing to the next level? For us, the answer was yes.

We knew from the beginning that for this operation to be successful we’d have to scale our production. We’ve already made a lot of progress, from the early 500 pound batches up to our current runs of 1250-1400 lbs. But we’ve run out of room to keep growing incrementally — it’s time to make a big jump.

This summer, we started planning the changes that will enable us to produce malt in proportions that will keep our customers satisfied year-round. As we find our malt in more beers and bigger batches, the increased capacity will allow us to work with new brewers across the state and throughout the South.

Here are some of the changes that have been happening over the past six weeks:

Racks

These new storage racks will hold up to 100 tons of bulk grain storage, plus capacity for 15 tons of finished malt. Along with our increased storage, we’re going to start packaging our malt in one-ton “Super Sacks”, which should make things easier for some of our larger clients. For those who work with 50 lb. bags, we’ll still be using those too!

Can you spot our new sign?

Steep Tanks

We can’t wait for our new, shiny, 1,500-gallon steep tanks to arrive from our local fabricator (ProSteel). These are where the grain will steep for three days, soaking up the water that will signal it’s time to grow.

Germination Room

Our new germination room will give us much more space than we had before. Once it’s been deep-cleaned, we’ll be able spread some 8,000 pounds of grain on the floor to germinate. While we could look at buying automated or mechanical rakes for turning all that grain, we’re going to stick to traditional floor malting as it imparts additional flavor and character to all of our products. Applying this approach to a much larger batch will take more time and effort to manage, but the quality and flavor will be worth it!

Kiln

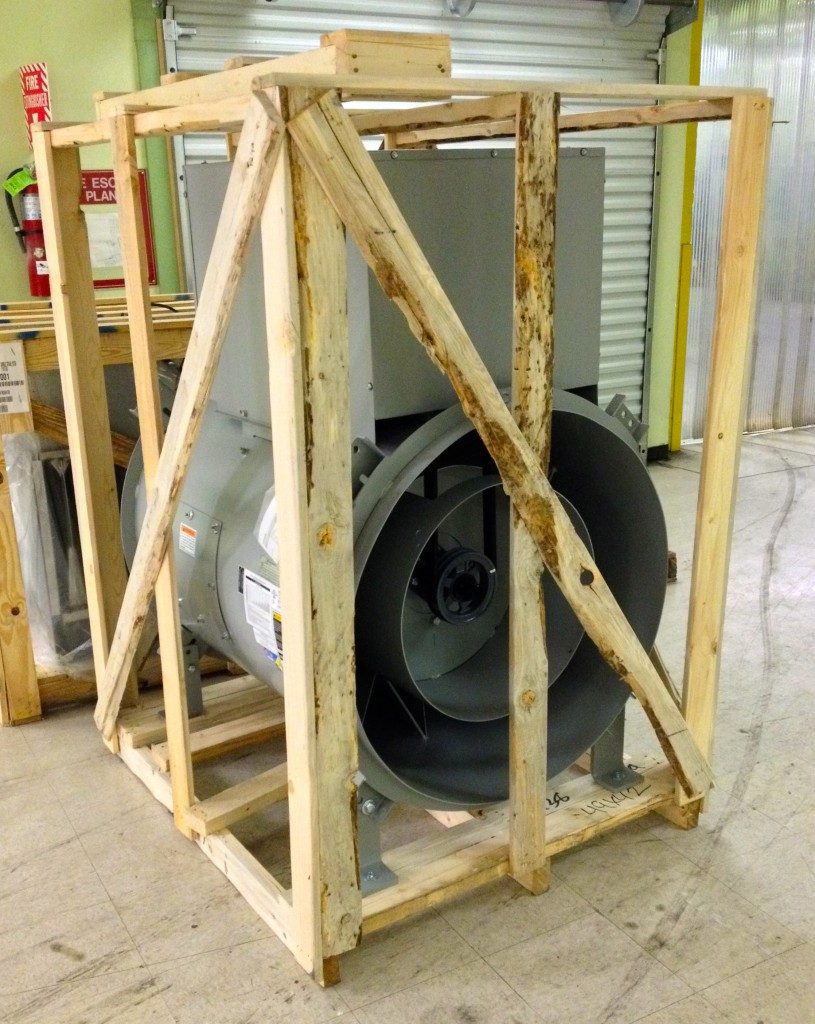

Over the past two years we’ve learned a lot about building and maintaining a small malt kiln. Our first few (failed) attempts in 2011 led us to implement a vastly improved ductwork design and a stronger fan. Once we got the basics taken care of, we teamed up with our friends at Control Specialties, Inc. to help with automation and process controls. Byron Watkins and his team have been invaluable to us, helping maintain our current kiln and designing the next one. Kiln 3.0 will mark a tremendous leap forward for us in terms of capacity, automation, and efficiency.

Putting the final touches on the insulation.

This new fan’s gonna purrrr as it blows warm air through the kiln.

Seed Cleaning Machine

Thankfully, our current debearder has the capacity to grow with us, so we were able to “save” some money on that front. However, a new, high-capacity seed cleaner was definitely in order. A refurbished beauty (circa 1960) is set to arrive in late December and should allow us to clean the entire 8,000 lb. batch in less than 2 hours!

The Great Unknowns…

You must be thinking, “Wow, these guys have this thing completed dialed!” Not so fast my friend. We’ve got some new equipment coming in that we’ve never worked with before. Bucket elevators, v-belt conveyors, bagging scales…the list goes on and on. We know that they’ll fit and what they are supposed to do, but we still have to put them into action! Stay tuned to the Kiln Blog — I’m sure we’ll have a few good stories to tell.