We’ve heard it since the beginning…..it can’t be local enough!

– Brent Manning

We’ve offered locally-sourced malt for almost a decade now. While this practice marks a notable improvement in the carbon footprint associated with producing craft beer and spirits, others want to take it one step further.

That is where contract (aka toll) malting enters the conversation. Toll malting allows our customers to bring grain from their family farm to the malt house and then back to the brewhouse or distillery, allowing for a true taste of home to be infused into their products.

We recently completed a project with Pretoria Fields Collective out of Albany, GA that helped them connect the dots between their farm and their fermenters. We worked with their farmer to manage variety selection and crop management during the growing season. Following harvest we worked with their brewer to develop two different malts that could be utilized throughout their product line.

“Working with Riverbend on a contract malting project allowed us to utilize our estate grown barley in several special projects over the past year” said Dee Moore Head of Brewing Operations for Pretoria Fields. “Integrating these special malts into our production aligns with our core values of sourcing as much as possible from our local, family-owned farm.”

What’s involved in the process you ask? Read on…..

Initial Consultation – September

We work with winter grains, so the best time to kick things off is late summer. We can provide guidance on variety selection, required acreage, and handling recommendations.

Crop Management – October – May

We’ve forged a partnership with researchers from NC State and Virginia Tech to provide the technical background necessary to produce high-quality grain. Producing great barley doesn’t happen by accident and we’ll do our best to connect you to our network of resources.

Harvest – June

After months of watching the crop, it is time to test and evaluate the harvest. We’ll walk you through the finer points of quality evaluation and give you an honest opinion on what is possible with your grain.

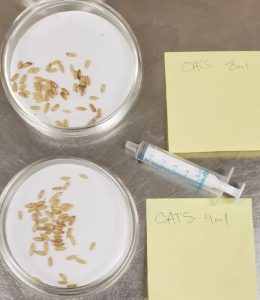

Malting – August

Assuming quality specifications are met, we’ll take delivery in late summer. From there, we’ll run the batch(es) through our system over the course of seven days. This might produce a great, multi-purpose base malt or something special that is included in annual “estate” offering.

We’ve handled a wide variety of small grains and love a challenge. Give us a call if you have a project in mind!

- Brent

This was a great meal. Matt and I joined one of my buddies from college for an exploration of oenobeer at

This was a great meal. Matt and I joined one of my buddies from college for an exploration of oenobeer at