Homebrewing was an integral part of our early development and we are excited to celebrate National Homebrew Day on May 7th!

I started homebrewing back in Wilmington with an old 5 gallon pot and igloo cooler. I cobbled together a gravity system with old chairs and end tables in the driveway for those early brews. I always tell people that I had “Dogfish Head Syndrome” when it came to recipe design. Whole fruit, spices, and other adjuncts were all on the table….and I had no business adding these things! A particularly gnarly batch of Winter Warmer comes to mind…way too much ginger!

Then I picked up a copy of “Brewing Classic Styles” by John Palmer and “Designing Great Beer” by Ray Daniels. These two books marked a sea change in my approach to brewing. Out with the spices and in with the classic, fresh ingredients! Zeroing in on ingredients and process improved the quality of my beer in just a few short months!

The hobby gathered steam as I began diving into podcasts like Brewing with Style from The Brewing Network. The show, hosted by Jamil Zainasheff, takes a deep dive into each style, explaining the history, ingredient selection, and important process tweaks necessary to reproduce more technical styles.

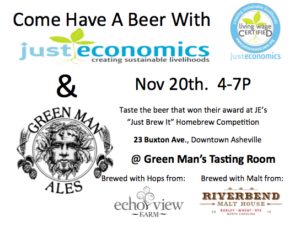

All of the accumulated knowledge and experience came in handy as Brian and I began to explore the world of malting. As Brian often points out, I was hesitant to malt a 6-row variety as it was not the preferred barley in a vast majority of the styles I had explored. However, I did understand flavor contributions and brew house performance….which quickly changed my mind about Thoroughbred. Just a quick mill adjustment and we were getting great flavor and decent extract from our early test batches. We entered one of these in a homebrew contest and were chosen by Mike Karnowski from Green Man (now Zebulon Artisan Ales) as his favorite!

This is just one of the “happy accidents” that got us where we are today. Happy National Homebrew Day and we look forward to sharing more memories as we explore our 10 year history over the next few months!

Here’s the original recipe….

| RMH – Pale Ale Malt (4.0 SRM) | 86.30% |

| Vienna Malt (RMH Test Batch) (5.0 SRM) | 5.90% |

| RMH-White Wheat (4.0 SRM) | 3.90% |

| Cascade [4.50 %] – Boil 60.0 min | 37.7 IBUs |

| Cascade [4.50 %] – Boil 15.0 min | 5.0 IBUs |

| Cascade [4.50 %] – Boil 0.0 min | 0.0 IBUs |

| Pacific Ale (White Labs #WLP041) [35.49 ml] |