After months of installing, calibrating, and troubleshooting our new equipment, we finally have the various components of our expansion dialed in. We’ve done several runs now with everything in place and though we’ll continue to make adjustments as we go along, we’re excited to get into a rhythm and focus on doing what we do best: making great malt.

Here are some of the final pieces of the puzzle to get us to where we are today. (Check out part one and part two of our expansion to get the full story.)

Bag Unloader/Auger

Using a forklift and this bag unloader, we can easily empty a bag of raw grain and load the steep tanks. This procedure can now be safely operated by one person. We load a super sack onto the frame, put the iris valve in the closed position while we open the bag, then open the valve and use the auger to carry the grain into the steep tanks. A control panel operates the auger and allows us to choose which tank to fill.

Brian starts a new batch, using the bag unloader to load the steep tanks.

Grain Conveyor

After the grain germinates on the floor for several days, we use this grain conveyor to help us load germinated grain into the kiln. With a few of us shoveling into the conveyor and one person spreading grain in the kiln, we can load the kiln in just a few hours.

Bucket Elevators

Three bucket elevators have helped us automate the cleaning process significantly. Sure, we still have to shovel grain out of the kiln, but the bucket elevators carry the grain from the kiln to the debearder, the debearder into the seed cleaner, and from the seed cleaner into a hopper equipped with a bagging scale, which we then use to fill 50 lb. bags. No more manually moving grain from machine to machine!

Seed Cleaner

This is the “crown jewel” of the cleaning and packaging operation, a refurbished Clipper seed cleaner, built in the 1950s! (We’re thinking of calling her “Bertha.”) It sorts malt through a series of screens, removing anything too small or too big for disposal. A large fan blows dust off the malt so the brewer gets a clean product. We can now clean and package nearly four tons of malt in half a day!

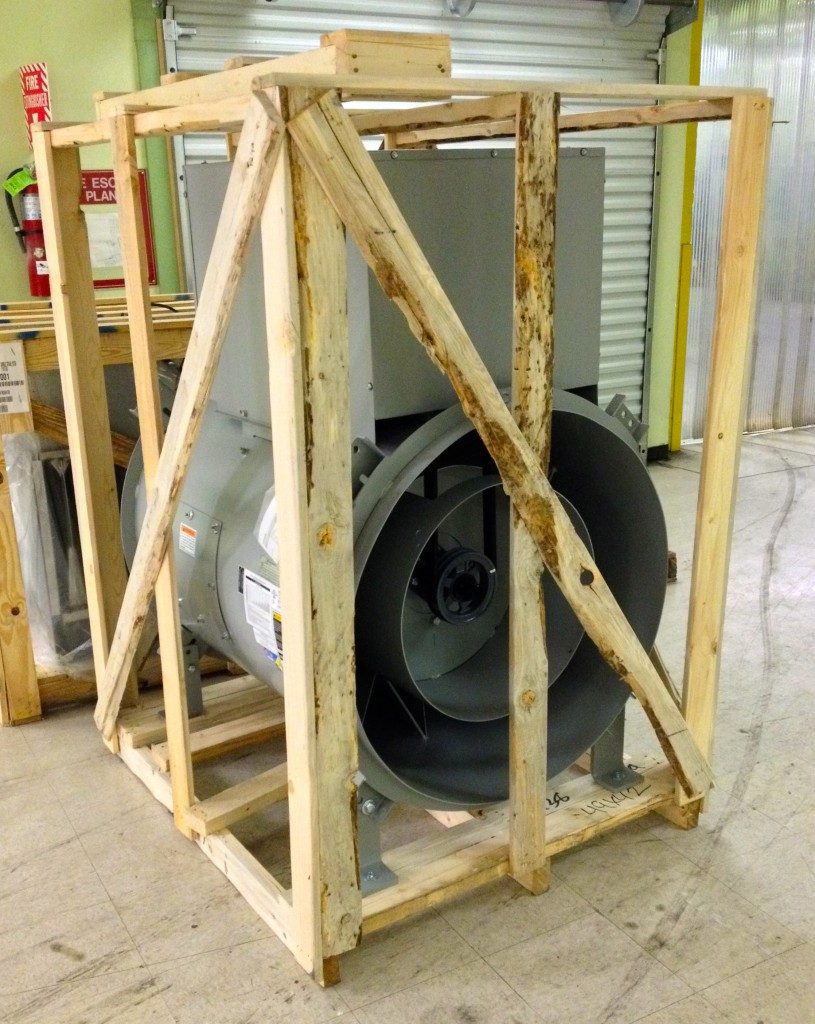

Dust Collector

This was one part of the system that presented some challenges. The dust collector we originally ordered just didn’t have enough power to handle the dust coming out of the seed cleaner, which uses air to blow the very fine material off the grain. A friend helped us source this bad boy, which provides more than enough suction to keep most of the dust out of the air.

Over the next several months we will enjoy our expanded capacity and a steady production schedule, but always in the back of our minds…what’s in store for phase 3?