Summertime in Tennessee means fresh fruit and vegetables, and lots of them at Farm to Tap. Harding House Brewing Co. in West Nashville celebrates this bounty with an annual green tomato Saison, Proleptic, that boasts fresh green grape flavors and bright effervescence. “I dare you to try it,” says brewery owner Nate Underwood. “It sounds crazy, but I love this beer because it represents our practice of looking to our area for ingredient selection. Our passion for brewing comes from agriculture, and green tomatoes are a big part of the agriculture in the South.”

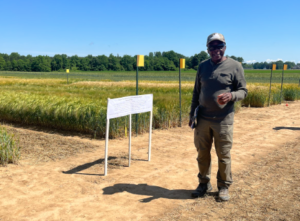

Underwood’s ag passion is helping to put Tennessee beer on the map. He’s one of the driving forces behind Farm To Tap (FTT), a partnership launched by the Tennessee Craft Brewers Guild and the Tennessee Department of Agriculture in 2021 to encourage Tennessee brewers to use Tennessee sourced ingredients in their beer. Underwood is so involved in this initiative, in fact, that you can’t really talk about this concept without including Nate in the conversation.

That’s what Sharon Cheek, Executive Director of the Tennessee Craft Brewers Guild, says. She credits Underwood with helping launch the program and for his advocacy around it, including speaking at the 2022 Tennessee Legislative Session to secure the program’s second year of funding with an increase from $350,000 to $400,000.

In year one, Farm To Tap kicked off with three events at Guild member breweries— at Harding House Brewing Co. in Nashville, at Printshop Beer Co. in Knoxville, and at Soul & Spirits Brewery in Memphis — aimed to engage the public in this initiative by offering flight tastings, brewery tours and panel discussions. Additionally more than 1900 tickets were sold for three FTT festivals that also took place in Nashville, Knoxville, Memphis. “The festivals brought together farmers, brewers and consumers for these interactive half-day events that included beer tastings, music, food trucks and other Tennessee vendors to enjoy,” says Cheek. “Additionally, more than 30 Guild member breweries showcased beers utilizing Tennessee grown crops and several local vendors also attended and offered their products for sale.”

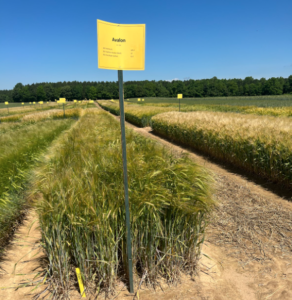

For Riverbend, a proud Tennessee Craft Brewers Guild member, festivals that showcase beer lists full of local ingredients are our kind of festivals. These exceptional showcases of Tennessee-grown ingredients and family farms are perhaps some of the largest compilations of craft malt the Volunteer State has ever seen.

“We’re honored to have Riverbend’s partnership from the very beginning,” Cheek adds. “From “what if” chats over beers, to informative calls about malted barley, the entire team has made themselves available to help the Farm To Tap mission succeed.”

Thanks are in order to Cheek and her team, to Nate and his crew at Harding House, and to all of the breweries involved. It’s our honor to participate.

Cheers to another year of Farm To Tap! Stay tuned and get involved at farmtotap.org.