Check out our new malt varieties to experiment with in your brewhouses and distillers!

What 2022 looks like for maltsters and farmers. Have questions?

Hard to believe we are about to close the books on 2021! I always enjoy going back through our social media feed and photos…remembering the conversations and beers that defined this roller coaster of a year. The list of my favorite beers below is presented in a loose chronological order, capturing the seasonality that plays a large role in defining experiences for me.

Munich Rye Lager – Hi-Wire

2021 kicked off with this beautiful release from Hi-Wire. This beer hit all the right notes for me in late winter. Perfect for that time of year when you’ve had enough “big” stouts but your palate is not quite ready for that first light beer of spring.

Their choice of malts created layers of biscuit, graham cracker, and toast at an approachable alcohol level. Noble presence was just enough to cleanse the palate and set the table for another sip. Bonus points for including recipe details in the packaging design!

VR Pizza Boy (Dortmunder Lager) – DSSOLVR

This was a fascinating and nerdy exploration into the terroir of barley varieties and malt house character. We received 2 tons of Talisman barley from our friends at Skagit Valley Malting and we sent them some of our Violetta. We applied our Southern Select recipe to the Talisman and the results were noticeably different. Lab analysis revealed lower levels of modification and corresponding color development. On the flavor front, we noticed more light cracker and less bready sweetness…..a malt stuck between Pilsner and Pale Ale profiles.

The good folks at DSSOLVR took this profile and ran with it! Tweaking water and mash profiles to highlight the malt character. The result was a thirsty quenching success!

Your Juice Sire (Sour/Wild IPA) – Little Animals Brewery

It isn’t everyday I have a “moment” with an IPA. Most leave me longing for the old days of crisp citrus and pine notes found in the classic West Coast examples. We hear tropical, mango, guava, etc. thrown around quite a bit when it comes to describing the modern IPA. To me, those bright and tantalizing flavors are often dulled by the overly sweet and creamy mouthfeel of the NEIPA style.

Ah, but this example from Little Animals lit me up!

They start with a mash bill that includes our Pilsner, Munich and Oats, add Idaho 7 and Belma then ferment with a blend of Saccharomyces and Brettanomyces. The final twist is where this beer takes flight…..a blend of barrel-aged blonde sour is added prior to packaging. This really sets off the aromatics and gives this beer a crisp, satisfying finish.

Biere de’ Riverbend (Belgian Dark Strong) – Fonta Flora

You knew this one would be on the list. Crafted as part of our 10th anniversary series, our homies at Fonta Flora really put something beautiful together. The mash bill brings in both of our Munichs and Sunset Wheat to build layers of complexity. Traditional Belgian yeast and dark candi sugar all contribute to rich fig, raisin, and toffee character in this one. The finished beer is disturbingly drinkable despite the 10% ABV.

They followed this release with Druidsickle, a bourbon barrel aged spiced ale….can’t wait to try that one!

Honorable Mention

Polotmavý Ležák 12º – Cohesion Brewing Company

I’ll admit, I had never heard of Cohesion when my friend Jen Blair mentioned them as a potential meet up spot in Denver during CBC. Thirty minutes later I’m in the taproom geeking out with her and the brewer (Eric) about his decoction schedule!

Everything about this place is focused on traditional Czech-style lagers. Each of the beers were complex and beautifully presented via side pull faucets. What made the evening even more special was learning about the role craft malt plays in their brewhouse….turns out our good friends at Troubadour Maltings created several special malts designed to work with the decoction heavy approach.

This intersection of local malt and old-world craftsmanship is an excellent example of the innovation that will continue to propel craft beer forward in the years to come!

Happy holidays everyone!

Brent

It’s only natural to look out over a field of barley and reflect back to this time last year, or the year before that. This year we’re feeling extra nostalgic about our 10 year harvest that we’re now enjoying in craft beer across our region, toasting to a decade in business in what’s become a burgeoning agricultural industry. The craft malt story is unfolding, and we’re proud to help tell it.

How have the crops improved?

When we started, 6-row barley was the only game in town. A variety called Thoroughbred is where we got our start. Notoriously challenging to work with due to high beta glucan levels. We worked steadily to tease out the perfect blend of moisture, temperature and time required to promote proper modification. Now, in the twilight of its career, this variety continues to hold a place in our year-round lineup!

As we have gotten better, so have our farmers. They’ll tell you that they only get 50 or so chances in their lifetime to produce a quality product. We’re happy to report that most have been quick learners… developing programs that have increased test weight and yields over the years.

We’ve also gained access to several 2-row varieties that really helped open the doors at large-scale breweries for us. Violetta, Calypso, and Flavia all consistently yield >80 bushels an acre.

How did they look this year?

Mother nature was good to us! She spared us a late season frost and rainfall levels were manageable. Late season rains can often lead to pre-harvest sprout damage, but that was not the case in 2021. Most of our growers reported high overall quality and solid yield numbers. This gives us a solid foundation to work with until next summer!

Our friends out in the Western United States were not as lucky, dealing with drought conditions. Rainfall of only 5-6 inches was reported in some areas, which creates stressful growing conditions for barley. The end result is high protein and corresponding lower extract levels in the finished malt.

How have relationships with farmers gotten stronger?

Open and honest communication has been a cornerstone for us. Each year our “crystal ball” comes into a bit better focus, this helps us provide better estimates on raw material requirements to our network. Early on, our estimates varied wildly depending on what sale opportunities were falling into (or out of) the picture. Combine that variability with a fledgling grain growing effort, and you get a recipe for disaster.

2018 was probably the toughest year for all of us. We were ramping up production with a harvest that was less than stellar. Our growers and seed cleaners worked hard to get us the best material they could at an accelerated pace. It was a challenging time; frayed nerves were the order of the day. When 2019’s harvest arrived, we breathed a sigh of relief and went to work.

Our growth has allowed us to expand contracted acreage throughout our network and strengthen our commitment to #maltwithamission.

What’s next?

New varieties and new partners throughout the South. Early on, we built relationships in 10 acre increments, which equates to a truckload of grain. The need to scale shifted our focus to 50 and 100 acre increments to ensure adequate supply of craft malt. As we look to our second decade, we want to return to our roots and support small-scale pilot projects that offer access to a broader array of stakeholders in our region.

Cumberland Corn malt beckons down-home flavor and a rich sense of tradition. The pleasant combination of fresh cornbread and subtle toastiness are balanced by its earthy undertones. Tennessee-grown, this corn malt delivers an ethereal sweet flavor that doesn’t require a separate cereal mash. It complements a wide array of beer styles– especially American Lager— and it makes for a storied, local addition to a Bourbon mash.

Corn based-beers are trending at Southeastern craft breweries; here are some made with Riverbend Cumberland Corn malt.

Alliance Brewing’s Alliance Lager – TN

At Alliance Brewing, beer is a catalyst for uniting people. The ability that a bold house lager has to bring folks together is an impressive one; some would attribute it to its locally sourced craft malt.

A gorgeous clear gold with a frothy head, this lager is super crisp and clean with just a whisper of a light, cereal body. A subtle earthy, sweet flavor from Riverbend Cumberland Corn balances its bright freshness, making Alliance Lager a perfect easy (day) drinker.

Thirsty Monk Contemplate Cream Ale – NC

Doesn’t take a whole lot of contemplation to fall in love with Thirsty Monk’s Contemplate Cream Ale.

Brewed with Cumberland Corn, as well as Riverbend’s Chesapeake Pils Malt and Bloody Butcher Corn, Contemplate packs a lot of complexity for its easy-drinking style. Aromas of sweet almond liqueur, white bread crust, and summer harvested corn lay the foundation for subtle notes of white grape and spiced pear. Fresh cornbread flavor and nutty character allow for a balanced finish. This ale is light, smooth, and crisp with a gentle refreshing bitterness.

YEE-HAW Brewing Co’s Cerveza Mexican Lager – TN

South of the border flavors meet southern hospitality in this flavor profile of crisp Mexican-style Lager.

YEE-HAW’s Cerveza Mexican Lager is a delectable clash of cultures. The classic Mexican-style Lager you know and love is made with locally sourced malts and flaked corn courtesy of Riverbend. The result is a creamy, slightly hoppy brew with a smooth, clean finish. It’s light, it’s crisp, and oh so delicioso.

Beacon Brewing Co.’s Waves of Grain – GA

Oh beautiful, for spacious skies, for Beacon Brewing Co’s amber Waves of Grain Lager.

Waves of Grain is Beacon’s take on a craft American Light Lager. They use our Chesapeake Pilsner malt and Cumberland Corn malt for some southern terroir. Add a hint of fruitiness from a small whirlpool addition of Loral and you got yourself one refreshing beverage. 100% naturally carbonated beer-flavored beer!

Riverbend turns 10 and creates their anniversary Sunset Wheat. Find details here.

Hillman Beer Company

If we had a nickel for every conversation we had with small batch producers about why craft malt is the sustainable, marketable choice for ingredient purchasing… well let’s just say we’d have a lot of nickels.

Enter a hot steep demonstration that we’ve fondly coined the “craft malt pepsi challenge” in which we compare the flavor profile of Riverbend malt to that of larger commodity brands. The contrast is stark.

A couple weeks back, we engaged in this hot steep juxtaposition with long-time Riverbend customer Hillman Beer Company who we’re pleased to report just made the switch to Riverbend as its primary base malt provider. Hillman has always had around 15 percent of the beers on their board made with our malts, and it’s an honor to say that number has jumped to around 85 percent.

“We love having Riverbend as neighbors,” says Co-Founder Brad Hillman. “We love that we can say all the malt is grown within 500 miles from Asheville. For customers, it’s cool to know that your beer is grown locally. It’s also cool to know you’re supporting local farmers. There are so many different things to be proud of here.”

In April of this year, Hillman joined the Craft Malt Certified™ seal, a pledge to purchase ten percent or more craft malt as part of total annual malt purchases. That was a no-brainer for Hillman, who is already using Riverbend’s Chesapeake Pilsner for their Kölsch and Old Fort Original Lager, and pretty much any other beer that requires Pilsner malt,” Brad adds. He uses Riverbend’s Southern Select as a “nice in-between base malt between Pilsner and Marris Otter,” and Streaker Oats make their appearance in many of Hillman’s Belgian-inspired and sour beers.

Next up for Hillman is an Amber Rye Lager made with Riverbend’s Carolina Rye malt and Munich Rye malt varieties, releasing in mid-December.

“The proof’s in the beer,” Brad says. “Their malt is just great.”

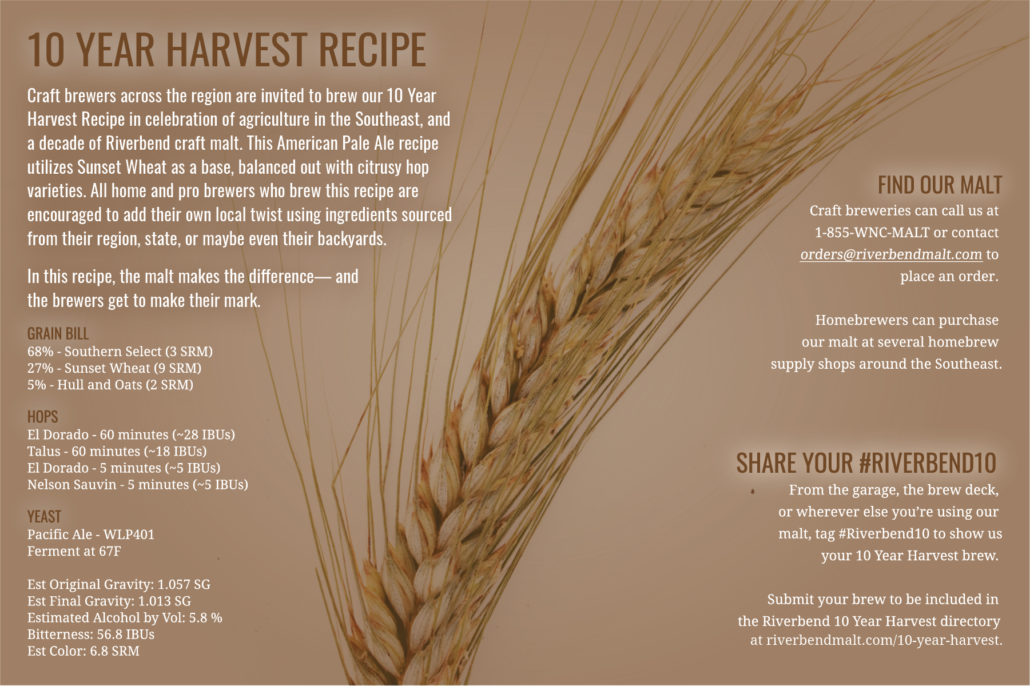

Craft brewers across the region are invited to brew the Riverbend Malt House 10 Year Harvest Recipe in celebration of agriculture in the Southeast and a decade of Riverbend craft malt.

The #Riverbend10 Wheat Pale Ale recipe utilizes the Riverbend anniversary Sunset Wheat as a base, balanced out with citrusy hop varieties. In this recipe, the malt makes the difference— and the brewers get to make their mark. By design, this pale ale is a clean, malt-forward canvas for showcasing local agriculture. All home and pro brewers who brew this recipe are encouraged to add their own local twist using ingredients sourced from their region, state, or maybe even their backyards.

Find our malt at these homebrew supply shops.

Tag #Riverbend10 to show us your 10 Year Harvest brew!

Submit your recipe to our anniversary beer log here.

It’s official! American Single Malt Whiskey will become a new category for spirits across the United States in early 2022. The American Single Malt Whiskey Commission has been hard at work for years now to make this happen. We tip our hats to them.

The category will be defined by the following criteria….

- made from 100% malted barley

- distilled entirely at one distillery

- mashed, distilled and matured in the United States of America

- matured in oak casks of a capacity not exceeding 700 liters

- distilled to no more than 160 (U.S.) proof (80% ABV)

- bottled at 80 (U.S.) proof or more (40% ABV)

As you can probably imagine, we are excited about this new development. It offers an excellent opportunity to explore the world of craft malt flavor in a distilled format… the intersection of art science for both maltster and distiller!

Most Scotch Whisky is produced using a Pale Ale style malt (think Maris Otter) that can be kilned with or without the introduction of peat smoke. In this case the maltster is delivering a nicely balanced package of rich, bready flavors along with sufficient enzymes to support efficient conversion. These malts combined with pot still based production runs yield a spirit with substantial mouthfeel and complexity.

But what happens when we explore different varieties of barley or higher kilned specialty malts within these same production techniques? What happens when we utilize column or hybrid stills? What happens when we experiment with different proof levels coming off of the still?

To quote my friend Jason Parker from Copperworks Distilling Company… ”We get to write the book”!

Craft maltsters across the United States work with numerous 2-row and 6-row varieties of both Winter and Spring barleys to create a wide range of flavorful base malts that will support this new style. Our experience with Southern-grown winter barley has demonstrated distinctive and consistent differences in varieties that range from biscuits and hearth-baked bread to floral and melon notes. These nuances will undoubtedly have a positive impact on the finished spirit.

Riverbend’s Munich “family”…Vienna, Light Munich, and Dark Munich

Incorporating Munich-style malts into the grain bill will also set the table for an exciting departure from the norm. More sweet aromatics like honey, vanilla, and cake batter will now be present and available to contribute flavors to distillate that haven’t been thoroughly explored. Couple this with variations in climate that impact the aging process and you have the building blocks of terroir for American Single Malt.

While not technically keeping with the new definition of the style, the classic rye versus wheat debate in bourbon could also spur additional avenues for innovation for American Malt Whiskey. Gently kilned soft white wheats might introduce delicate floral notes similar to fine pastries. Heirloom and modern rye varieties could contribute rich, earthy spice reminiscent of pumpernickel bread.

Last, but not least, we have smoke. Native hardwoods, fruit woods, and decommissioned barrels could all play a role in building unique character. Several of our customers have already begun to experiment in this space and we are waiting patiently for the first releases to be bottled!

Got an idea for a unique grain bill? Want to discuss a custom malt project for your distillery? Give us a shout. We look forward to exploring this new chapter in artisan spirits together!

From pumpkin ales to Oktoberfest biers — fall is in the beer.

Asheville’s Riverbend Malt House is a key component in producing these autumnal flavors, which won’t last long on tap across the Southeast this season. Don’t miss these fall beers made with Riverbend craft malt.

Hillman Beer

Hillman Festbier is brewed with a combination of Riverbend Malt’s Chesapeake Pilsner, Vienna, and Light Munich malts. The result: a light, crisp, and complex beer perfect for sipping at the start of fall.

Swells’a Brewing

Swellsa’s new Oktoberfest Märzen, Oct-toobs Fest, is made with 100% North Carolina malts from Riverbend Malthouse and is a quintessential Bavarian lager. A full amber body with balanced sweetness and a dry finish make this lager highly drinkable, and delicious.

DSSOLVR

Hey Hey Yah Yah is DSSOLVR’s inaugural Festbier. Mashed with 100% Riverbend Malt grist, it’s composed of a blend of Chesapeake Pilsner, Light Munich, Vienna, and Chit malts hopped with Hallertauer Mittelfruh. It’s fermented low and slow with DISSOLVR’s house lager yeast, and finally sounded for natural carbonation.

Oklawaha Brewing

Meet Oklawah’s first-ever Festbier! Featuring Riverbend Malt’s Cumberland Pilsner, Vienna Malt, and Biscuit Malt, this beer is a glass full of sunshine to wind down summer. Crushable and light with a sweet biscuit-y, it’s a perfect early fall brew.

Crooked Can Brewing Company

Using a small, handcrafted batch of Florida grown rye malt from Riverbend Malt House, Flo-Rye-Da Pumpkin Ale is a true celebration of the season. Warmed bread and baked spice flavors from the rye pair perfectly with the 100 pounds of all-natural pumpkin puree in the mash. Added hints of cinnamon and nutmeg round out a sweet spiciness that makes this beer an autumn obsession.

Printshop Beer Co. & Next Level Brewing Knoxville

This killer Oktoberfest Marzen collab is the lovechild of two beloved Knoxville breweries. Bruno Marzen is crafted with Riverbend’s Base Camp and Great Chit malts, with a dash of both light and dark Munich Rye for a little spice. Crisp and addictively delicious, this Marzen is a great way to celebrate the season. Prost!

What Riverbend craft malt are you sipping this season? Show us your beers with #madewithRiverbend on social!

Let’s brew up something good.

Talk to our expert maltsters about the best malt for your project or work with us to create a custom malt.